The filtration system of Delta-Xero’s DX1000 series is designed to maximize the outstanding filtration quality of the cellulose capillary filter element. It offers units suited to filtering smaller oil tanks around 1000-2000 liters, as well as large tanks with 10,000 liters + (e.g. turbines).

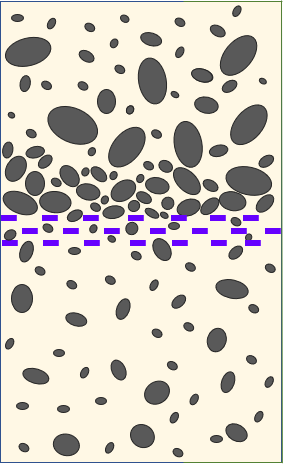

Filtration with DX1000 units can remove particles down to 0.1 micron as well as water (free and bound). The machine to which the filtration unit is attached can run non-stop while being filtered, and after 2-3 months the oil will be as clean as, if not much cleaner than, new oil. Since the filter element is a depth-type filter that holds contaminants with its entire capacity rather than simply catching them with the surface. This means that it can capture a large volume of contaminants plus water without clogging up. One filter element can hold 3-5 kg of particles.

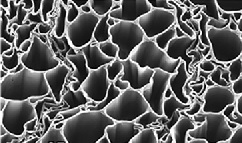

“Cellulose capillary filters” are made through patented technology in which the cellulose is made into countless small tubes like the capillary tubes of trees. This makes the cellulose capillary filters more effective than any other filter in the market, as it can capture contaminants as small as 0.1 micron.

A. Cellulose Capillary Tubes

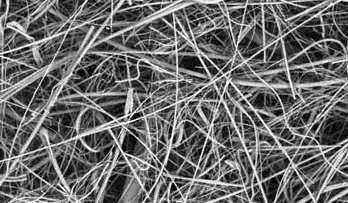

B. Surface-type filters

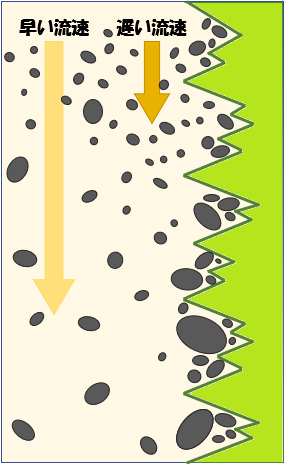

Compared with the surface type filters that are made by condensing fiber to capture contaminants over a certain size, with the cellulose capillary filters the oil travels relatively slowly, and the particles in the oil are drawn to the sides of the tubes. Smaller particles that surface-type filters cannot capture are removed effectively by the cellulose capillary tubes.

C. Cellulose Capillary Filter |  D. Surface Type Filter |

This means that the oil is constantly kept cleaner than new (unused) oil. Furthermore, removing the smaller particles stops the oxidization inside the oil, thus controlling the total acid value too. Usually oxidants that are unremoved by filters and remain in the oil systems turn into sludge and varnish, but the cellulose capillary filters removed these precursors and protect the system. As ongoing cleaning is carried out for several months, the super-clean oil will flush out the sludge and varnish accumulated inside the system.

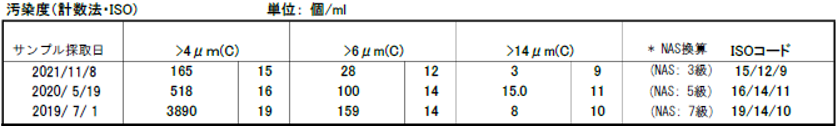

The following data is taken from a hydraulic system in Japan that was filtered using the cellulose capillary filters of Delta-Xero. Non-stop filtration for 2 years has maintained the oil in a cleaner condition than new oil. New oil actually contains many contaminant particles, which means an oil change (apart from the occasional top-up) would be detrimental to the system.

Filtration Like No Other

NAS code = 00. 5 years without oil change

Cellulose capillary filters are now in use in Japan in the metal processing, paper manufacturing, semiconductor manufacturing, machinery manufacturing and other industries. In Europe they are used in wind power generation and other power generation industries such as thermal and hydraulic, as well as construction machines, marine vessels, off-shore platforms, and many other industries. This filtration technology is used not only with lubricant, hydraulic and turbine oil, but also filtering diesel engine oil, which drastically reduces harmful exhaust gases such as NOx.

Lubricant oil deteriorates due to heat, oxidation, multiple reactions between the metals, and degradation or depletion of the additives contained in the oil. But the greatest contributor to oil deterioration is the contaminants inside the oil. Conventionally, electrostatic oil cleaning has been used, in which electricity is used to condense the minute contaminant particles into larger particles before they are filtered. Delta-Xero, however, employs a much simpler structure, but due to its originally developed cellulose depth-type filtration element is able to achieve a far greater level of filtration compared to the electrostatic filter machines. This allows the oil to be constantly kept cleaner than unused oil, adds longevity to the machinery and its parts, and great reduces the cost of maintenance. I highly recommend all to purchase this excellent product for your machinery.

JSD Ltd. Technical Advisor, Minoru Fujita, PhD

Doctor of Engineering

Consultant Engineer (Chemical)